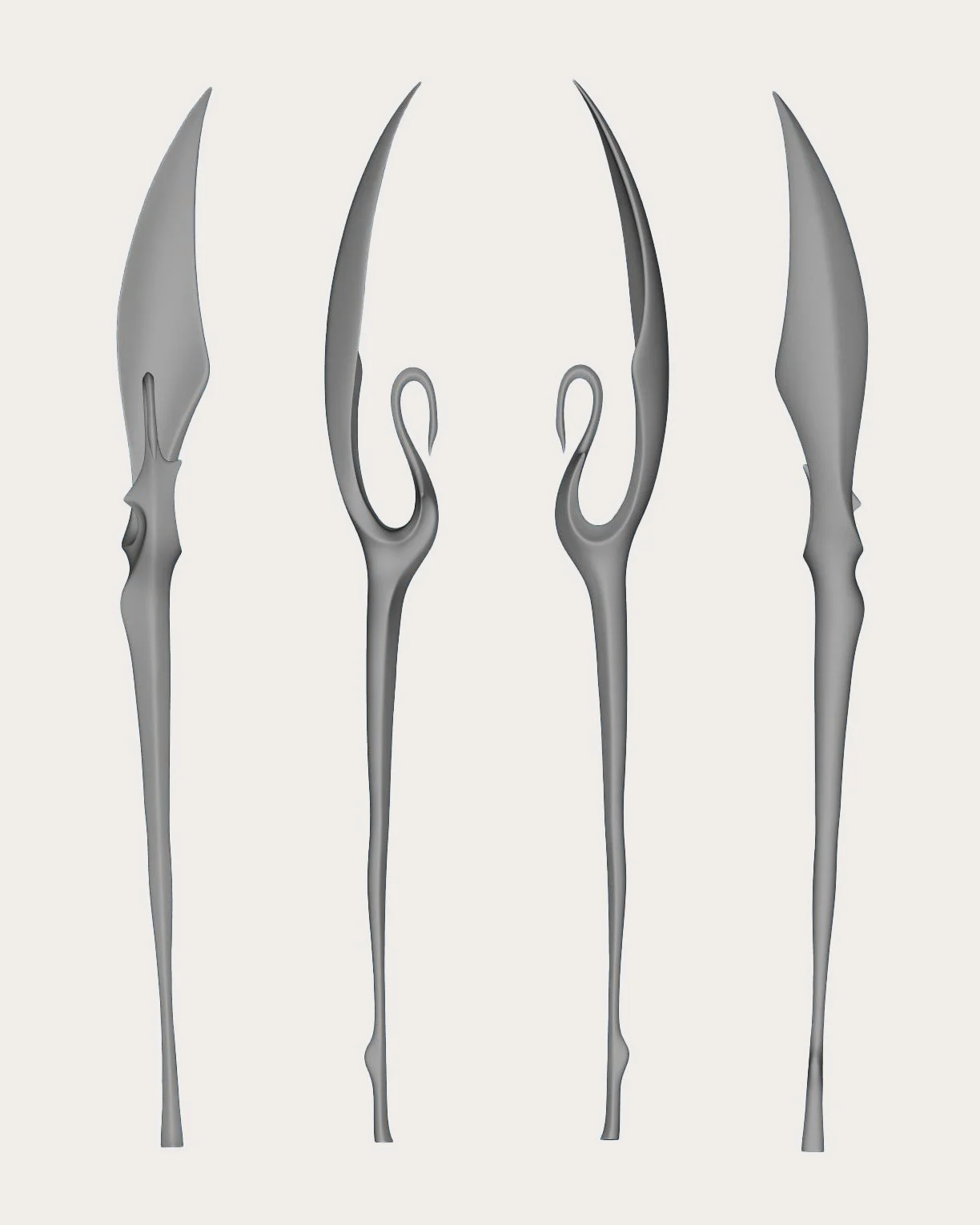

MAJESTIC

CHARLES WESTGARTH

Enlargement of an abstract bronze dancer, digitally scaled and fabricated for casting.

- Preserving the artist’s original expression while saving time, cost, and material.

CLIENT AND CONTEXT

Sculptor Charles Westgarth was commissioned to produce a new large-scale version of his work Majestic, part of his Abstract Dancers series. The original piece was hand-sculpted in a smaller format, but the client requested a significantly larger version for installation.

Rather than manually re-sculpting the piece at scale—a time-intensive and resource-heavy process—Charles approached Matter to develop a digital enlargement and fabrication strategy that retained the original form while enabling efficient production.

BRIEF

Precise 3D capture of the original sculpture

Scalable digital model with preservation of subtle surface details

A fabrication-ready pattern suitable for direct sand casting in bronze

Division and production using mixed digital manufacturing techniques

SERVICES PROVIDED

High-resolution 3D scanning of the original sculpture

Digital model clean-up and enlargement

Segmentation and prep for hybrid fabrication (CNC + 3D print)

Coordination with bronze foundry for casting specifications

PROCESS BREAKDOWN

We began by 3D scanning the original Majestic sculpture using a high-resolution photogrammetry workflow. This process captured the subtle surface qualities and form dynamics with fidelity, creating a solid digital base for further work.

The 3D model was then digitally scaled to the new dimensions required by the artist.

The model was digitally segmented for fabrication. It was cut so the piece could be fabricated by milling, as it is a 2.5D process, the geometry was cut to prevent any undercuts.

The model was CNC milled into foam. The body and legs were split down the middle and milled from one side only, whereas the wings were milled on both sides by flipping the material and milling the reverse side to complete the geometry. The head section was produced by 3D printing as the geometry was more complicated.

The pieces were then sanded and joined together into the sections that were to be individually sand cast.

The mould pattern was used in the casting process twice to create a pair of sculptures.

The sculpture was cast in three sections. The artist welded, sanded and polished to create the final bronze.

Once completed he applied a blue green patina and then sanded and polished back some edges to create the bronze highlighted edges.

The sculptures were set on a bronze display plinth and mounted facing each other.

RESULT & IMPACT

The new Majestic sculpture was successfully cast in bronze and installed per the client’s specifications. By digitising and scaling the original work, the artist was able to fulfil the commission without resculpting from scratch, saving both time and material cost.

The final piece maintained the dynamic energy of the original sculpture, with an exactitude that enabled direct integration into the foundry’s workflow.

No manual resculpting

No mould-making or production of waxes

Lower production cost

Faster project delivery

Artistic integrity preserved